All on the quiet, the Mashonaland Central’s sleepy capital, Bindura, is being transformed by the university it has hosted for the past 23 years – the Bindura University of Science Education (BUSE), which is now into all sorts of things to improve life up north, thanks to massive support by the Second Republic. What’s more: several innovations made by BUSE will not only impact life in the north but the country as a whole. Our Managing Editor, Baffour Ankomah, reports.

Last October, after officiating at Bindura University’s graduation ceremony, during which he commissioned three new buildings on campus, President Emmerson Mnangagwa wrote in the university visitor’s book: “Bindura University will be pivotal in the country”. He could not have been a better prophet. For, it is exactly what that relatively young university is doing to the country and to Bindura, the sleepy capital of the Mashonaland Central Province.

Only 23 years old as a tertiary institution (it got its charter as a university in 2000), the Bindura University of Science Education (BUSE) is now playing in the league of the big boys – and beating them to boot! That is, if we judge BUSE by its recent accomplishments (lofty in all their ramifications) and the impact they will have on the nation and its economy.

“It is an exciting time for us. We are enjoying this. To be productive is more enjoyable,” BUSE’s Vice Chancellor, Prof Eddie Mwenje, told a visiting team of Brick by Brick editors on 24 April 2023. “When the President wrote in our visitor’s book: ‘Bindura University will be pivotal in the country’, I said we have to do things differently.”

And what differently has BUSE been doing? Several innovations that will have a lasting impact on Zimbabwe. The first is the development of a low-cost, environmentally friendly, and low-energy chemical process for the production of sodium silicate using sugarcane bagasse ash as the raw material.

Sodium silicate is the chemical which municipal authorities in Zimbabwe use to treat drinking water. One estimate says US$5m is spent each year by the municipal authorities to import sodium silicate. BUSE’s new development, therefore, will save the country that huge import bill.

The second innovation is an e-tolling solution, called Smart Card, that will save motorists precious time at tollgates across the country.

The third is an eye-treatment solution brought about by BUSE’s attempt to have a fully-fledged School of Medical Sciences whose core institute currently is an Optometry Clinic that treats all kinds of eye diseases and provides eye glasses while you wait.

The fourth is the development of refreshing and healthy juices and yohurt produced from the masawu fruit that Zimbabweans have forever eaten without thinking it could be turned into juices and yohurts to enhance their Vitamin C intake.

The fifth is the development of an ICT solution to manage the movement of parcels in the country in partnership with ZimPost and ZUPCO.

The sixth is the development of a mobile web application called SMART Connect to link smallholder farmers to lucrative markets.

The seventh innovation is an artificial insemination programme for goats and pigs, which is bound to increase not only the population of goats and pigs in the country but their sizes as well.

The eight, and no less important, is the development of an animal feed that is bound to revolutionise the health of chickens, goats and sheep.

“When the President says people are going to be upper middle class or have an upper middle-class economy, we are the ones who are bringing it. And who doesn’t want to see people’s lives being improved? That’s exciting,” says Vice Chancellor Prof Mwenje, attributing BUSE’s phenomenal success to the Second Republic’s support to the university and the government’s Education 5.0 policy, which he says has been a game changer.

“I think the vision is exciting, where we are getting to is exciting. It is not about the challenges that we are going through, it is the vision, where we are getting to, where people can say their lives are better, and they can say ‘look, this is what BUSE did and this is what the communities did. I think the government is really putting its energy and money where its mouth is. It is exciting,” the Prof Mwenje adds.

Sodium silicate

By far, the biggest of BUSE’s accomplishments in terms of the weight of impact on the country is the sodium silicate project. The breakthrough came as a result of years of research and innovation involving the screening of a wide range of bio-materials with the aim of producing sodium silicate.

In Asian countries, rice husk ash is used to produce sodium silicate. As Zimbabwe does not grow rice, or in any appreciable quantities, BUSE had to look elsewhere to find a suitable substitute material to produce sodium silicate. The breakthrough came when sugarcane bagasse ash was found.

More than 28 tons of sugarcane bagasse ash is produced per day as an agro-industrial waste by Green Fuels (Pvt) Ltd in Chisumbanje in the Manicaland Province. BUSE’s research found that 700 kg of sodium silicate can be produced from a ton of sugarcane bagasse ash, thus giving a recovery of 70%.

Which is very good news for Zimbabwe as a nation, because the City of Harare alone uses half a ton of sodium silicate per day in treating water at its Morton Jeffrey Water Treatment Works.

Sodium silicate is also used for the production of soaps and detergents, fire proofing materials, cementitious materials and resins, as well as mineral ore processing. It is also used in everyday purification of potable water by households in the country.

In 2022, the national demand for sodium silicate was estimated at 3,694 tons, and is projected to reach 12,849 tons by 2030, seven years from now. Currently, Zimbabwe imports the chemical from South Africa, the United Arab Emirates, and India.

Remarkably, when BUSE’s sodium silicate was tested by the City of Harare Water Quality Assurance Laboratory last year, it was found to be “an effective flocculant aid in water treatment at an optimum dose of 0.3 mg/L compared to an optimum of 0.5 mg/L required for imported chemicals”.

This shows that the BUSE product is more effective when compared to the imported variants, thus translating into a huge cost saving for the nation.

With these good results, BUSE is being supported by President Mnangagwa’s government to set up a plant at Chisumbanje to produce sodium silicate. This will contribute massively to the Second Republic’s rural industrialisation drive and uplift the rural communities spread around the plant, which is expected to create at least 500 direct jobs and several thousands of others in downstream industries.

It is expected that municipal authorities, mining companies, paper milling companies, detergent and soap producers, cement and resin material manufacturers, and makers of fire-proofing material will be the key off-takers of BUSE’s sodium silicate.

The university estimates that it can sell sodium silicate at US$1.10 per kilo against the current price of US$1.35 per kilo of the imported variant.

E-tolling

Another of BUSE’s innovations that will have a massive impact on the country is a “tollgate system” that uses tap-card technology to ease queues at tollgates. Targeting ZINARA, the tollgate system has been piloted and found to meet ZINARA’s requirements. The system has already been deployed at BUSE’s campus.

Instead of the current 10 to 12 seconds of standard time at tollgates (which can stretch even to a horrifying 5 minutes during the rush hour, depending on the state of the network provided by Econet, TelOne and NetOne), BUSE’s new tollgate system does the work in a maximum 8 seconds and a minimum 6 seconds.

When tested by ZINARA, BUSE’s system passed with an exceptional score, and is expected to be deployed by ZINARA in a first phase trial at the Esgodini tollgate (37 km from Bulawayo on the Bulawayo-Masvingo Road) and the Eskbank tollgate (18 km from Harare on the Harare-Bindura Road).

BUSE’s system removes user and booth operator interaction. According to Prof Courtie Mahamadi, BUSE’s Director of Research and Innovation, when a motorist arrives at a tollgate, he will just tap his card and the boom gate will automatically open.

“The motorist would have preloaded his card with money,” Prof Mahamadi explains. “There is an application, the express toll card app, that motorists would have on their phones. They will load their money there, it can be Ecocash or any other means we have in Zimbabwe for loading money, and the moment the motorist taps his card and pays the Zinara charges, the boom gate opens and off he goes.

“This has been demonstrated and it works. The advantage is that you can do the process under 8 seconds. That’s the maximum. You can actually do it under 6 seconds, but the maximum is 8 seconds. So the time that motorists pass through the tollgate has been reduced, currently it will go to even 12 seconds or one minute or even longer, but our Smart Card system has significantly reduced that.

“Though not yet rolled out, we have been optimising processes, we are piloting it within the university system itself, and optimising all transactions, and now the system is good to be rolled out. ZINARA officials have been here and they have also checked the system and demonstrated that it works. The university is now working in partnership with ZINARA.”

Prof Mahamadi could not give a specific date when the system will be rolled out, “but I can say very soon because all the systems are up and good to go. From here, the next step is to have the system piloted at Esogodini and Esbank. Those are the two tollgates given by ZINARA, so that we really test the system in real time, and once that is done, the system will be rolled out nationally.”

According to him, the Smart Card system was inspired by “the amount of business time, even social time, that is spent on the roads. It is just too much. People get frustrated, so we want to cut down on the time spent at the tollgates.

“This is an access control system, so it can actually help any organisation that needs to have access control. So while a module is being tailor-made for the national roads, we can also develop modules as well for organisations that require to have access control in terms of entry to their premises,” Prof Mahamadi told Brick by Brick.

Currently, ZINARA pays a huge subscription annually to use software developed by vendors based abroad. BUSE’s system will therefore result in cost savings and economic development through import substitution. The system also has the potential of being exported to other SADC countries.

ZINARA has 36 tollgates nationwide, and BUSE’s system is expected to lead to 260 direct jobs during the construction phase and a minimum of 72 direct jobs for the maintenance phase. High-end skills such as programming, network engineering, and app development will be part of the human capital needs for the project.

“Once the project has been fully implemented on the 36 tollgates in the country, we will then move to the regional market with the product,” said Prof Mahamadi. This will bring additional foreign reserves for the nation.

School of medical sciences

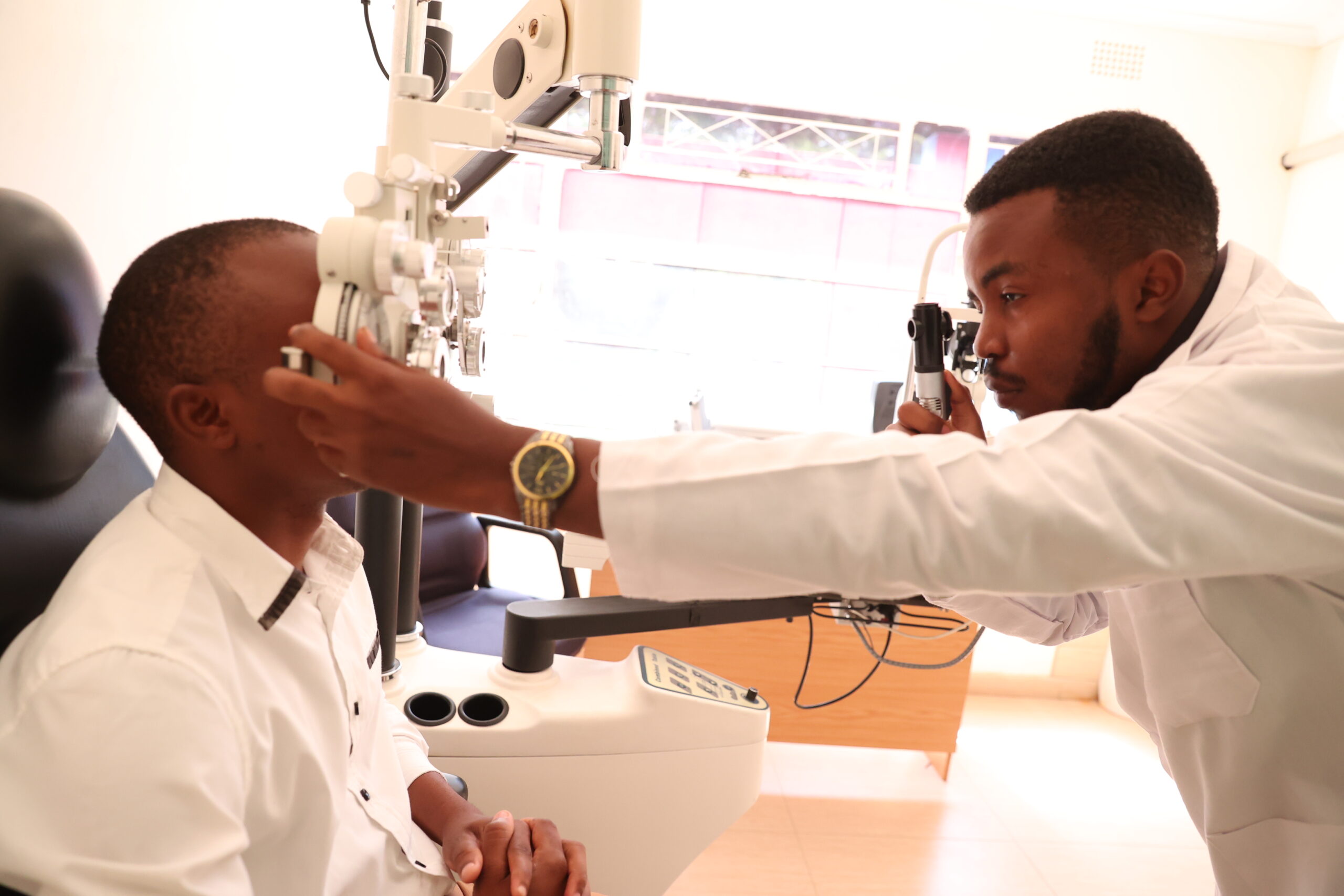

Another of BUSE’s new accomplishments is its optometry programme housed at the Optometry Clinic, which will be part of a larger School of Medical Sciences being built over a 1.6-hectare piece of land.

A first-class facility, the Optometry Clinic, commissioned by President Emmerson Mnangagwa on 6 November 2020, has become a place where Zimbabweans across the country, not just those in Bindura or the Mash Central Province, travel to for the treatment of various eye diseases. The Clinic also houses lecture rooms for the training of students.

The Clinic has a community outreach programme where lecturers and students go into communities near and far to offer screening and treatment services, as well as free eye glasses to deserving patients.

Prof Mwenje told Brick by Brick about one such outreach where a local chief, after receiving screening and free glasses, happily told them: “I could not read, but now I will be able to read whatever is put before me.” The Vice Chancellor said it dawned on him there and then that “if we had not started an optometric programme, all these people would still be in the dark. But now they are saying ‘we can see’. It is exciting.”

Collaboration with Ghana

The work and efficiency of the Optometry Clinic has been boosted by a collaboration between BUSE and the University of Cape Coast (UCC) in Ghana through which UCC sends lecturers and eye specialists to teach at BUSE and pass on knowledge.

When a Brick by Brick team of editors visited the Clinic on 24 April, two Ghanaian specialists were at work – Dr Michael Agyemang Kwarteng, and Evans Aboagye, a Senior Dispensing Optician.

Aboagye explained that they had come from Ghana under an MOU between UCC and BUSE. “We are here to train and guide students in optometry and also do community outreach,” he said. “In Southern Africa, BUSE’s work in optometry is the best – in both the training of students and the actual service to the community.”

When President Mnangagwa commissioned the Clinic in 2020, he was very pleased with the work of the Ghanaians. He tapped Aboagye’s shoulder in appreciation and told him he was doing a good job.

Aboagye gave the Brick by Brick editors a run-down of what happens at the Clinic. “If you are lucky to get a prescription [for glasses] in our stock, you can get your glasses from here in less than an hour from your initial examination,” he said. “In some cases, you can get your glasses in less than 30 minutes.

“Special prescriptions [for glasses] that take 3 months in other places to deliver, take just a week here. Even then we want to better it and make it a same-day delivery. That is what we are working towards – same day delivery of complicated special prescriptions.

“But ordinary prescriptions, no problem. You can get it in less than 30 minutes or at most in one hour. Patients may have come from a long way, so they shouldn’t wait too long to get their glasses, or made to go up and down waiting for their glasses, considering the economic factors involved such as transportation and the cost of travel.

“That is why, here at BUSE, we have put upon ourselves that if you come through our door, in less than an hour, your glasses should be ready.”

A happy Vice Chancellor Mwenje echoed Aboagye’s words: “This is one of the most efficient places in this country and even beyond,” he said. “You can get your glasses in the shortest possible time, more than you can get in any other place.”

Aboagye is the Optometry Clinic’s longest serving staff. He has been there for 5 years. According to him, in the past the optics used in making glasses came in glass form, but now science has given them a lot of advantages.

“In the past, when the glass fell down, we weren’t be able to pick it up again because it would have shattered. But now we have it in polycarbonate form, which is very good for children and certain professions. There are some glasses when there is a trauma on them, they break and perforate into your eyes. It is very dangerous.

“So looking at the disdavantages, science has come up with new products. Apart from the polycarbonate, there is the CR39 and traverse, which are more advanced, and they come in a very thin form, very thin technology. What we want to do currently at BUSE is what we call ‘the digital generation’. In Africa, we will be number two to do it, that is the way we want to go.”

The “digital generation” involves “progressive” glasses that are multifocal but can be generated from single vision, semi-finished lenses. “That is far, far advanced,” Aboagye explained, “and that’s what we want to do here in Bundura”.

So in the very near future, Zimbabweans will get advanced glasses produced in Bindura.

“When it comes to the advantages of the ‘digital generation’ compared to normal glasses, the digital is way, way, way, up,” Aboagye explained. “It reduces chromatic and surgical aberrations. So those are the heights we want to go here in Bindura. So we have put a blend in the training of students.”

The Clinic’s community outreach has been praised as it brings service and treatment closer to the people. “Aboagye and the other staff go and examine people right in the rural areas,” Prof Mwenje told Brick by Brick. “So it is not only seeing people who come to the Clinic, our staff also go on outreach – to Mbire, Mushumbi, Muzarabani and elsewhere. We go for a week or more, meeting the rural people and giving them examinations, treatment, and providing glasses for free.”

Aboagye teaches students all the practicals to do with opthalmatics, including cutting glasses. “I teach all that. And we thank God that our products and training are second to none. For the SADC region, we say BUSE is making strides.

“We cut the lenses with these machines here. But we also have 2,000 lenses in our store room here. If your prescription falls within the 2,000 lenses, you can get your glasses within 30 minutes. They will be ready for collection.

“What we have also done is to pass on cost savings to our patients, because locally the wholesale prices of glasses were, and still are, very high, making patients not able to bear the costs.

“So we looked at it, and got semi-finished products from our international suppliers in Japan, China, etc. So now the cost has been reduced. The Clinic has made savings, and the pockets of our patients too have become stable economically. So these are the little things we have been able to do here at BUSE.”

And all this is thanks to the massive support that the Second Republic has given to BUSE, as testified by Vice Chancellor Prof Mwenje in an interview published elsewhere in this issue.

CAPTIONS

Pic 1:

BUSE’s Vice Chancellor Prof Eddie Mwenje: “It is an exciting time for us. We are enjoying this. To be productive is more enjoyable … When the President wrote in our visitor’s book: ‘Bindura University will be pivotal in the country’, I said we have to do things differently.”

Pic 2:

BUSE ‘s Innovation Hub where most of the recent innovations have been incubated and implemented

Pic 3:

Prof Courtie Mahamadi, BUSE’s Director of Research and Innovation, demonstrates how the university’s landmark e-tolling system works

Pic 4:

Students of BUSE’s Optometry Clinic are taken through their paces. The Clinic will become part of a larger School of Medical Sciences that is being built at the same site

Pic 5:

Collaborating with Ghana: The work and efficiency of BUSE’s Optometry Clinic has been boosted by a collaboration between BUSE and the University of Cape Coast (UCC) in Ghana through which UCC sends lecturers and eye specialists to teach at BUSE and pass on knowledge. Here, Evans Aboagye, a Senior Dispensing Optician (left), who teaches at the Optometry Clinic explains what his work entails to Vice Chancellor Prof Mwenje (in work suit) and a visiting team of Brick by Brick editors,

Pic 6:

Evans Aboagye: “We are here to train and guide students in optometry and also do community outreach. In Southern Africa, BUSE’s work in optometry is the best – in both the training of students and the actual service to the community”